As a system furnisher for surface engineering, STS disposes of a extensive expertise portfolio. Included are degreasing, steel blasting, spinner blasting plants as well as manual and automatic coating specialized on adhesive and zinc fins coating.

As a conditioning step to coating, the faces are roughenend during the blasting and so exempt from rust, mill scale or welding cinder.

With output-regulated spinner-blasting plants (1-4 turbines), we are able to efficiently blast pipes, beams, welding groups and mass production small parts.

Blasting

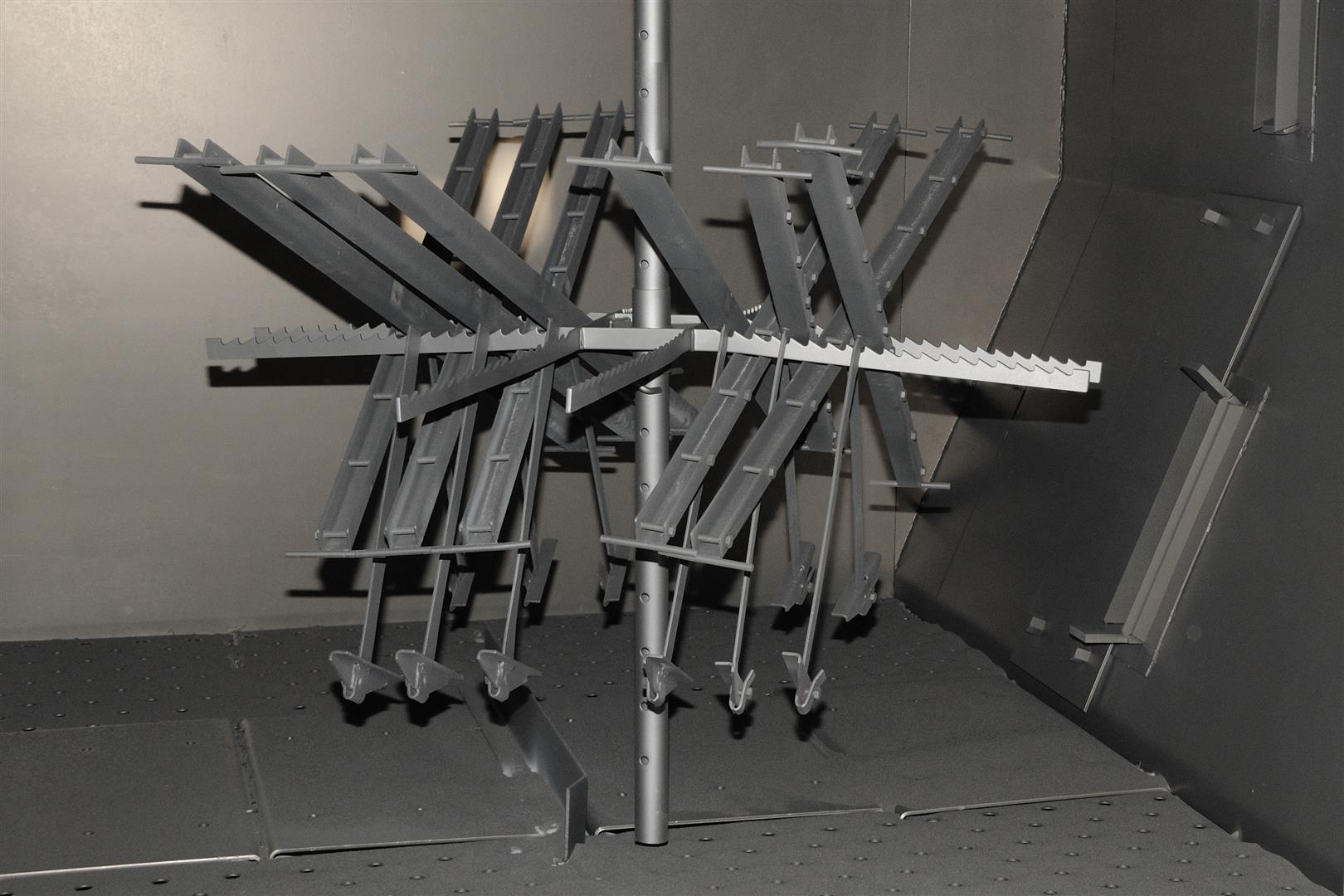

Suspension track blasting

The suspension track blasting plant is all-purpose for the treatment of rack goods.

Technical data:

Dimension: 2,90m high, diameter 1,60m

500kg charge weight

Automatic plant with oscillation, ongoing 360 ° rotating

Turntable blasting plant

The turntable blasting plant is ideal for roughening, derusting and descaling of surfaces of piece goods.

Technichal data:

Dimension: 40 cm wide * 40 cm long * 10 cm high

Unit weight max. 10 kg

endlessly rotating roundtable-unit

Throughput blasting plant

Via a full 360 ° treatment with 4 turbines acting from different positions, the throughput blasting plant is ideal for roughening and final cleaning of rack goods and piece goods.

Dimensions: largeur 100 cm * longueur 600 cm * hauteur 80 cm

Unit weight/Max weight: 2.500 kg

Continuous process

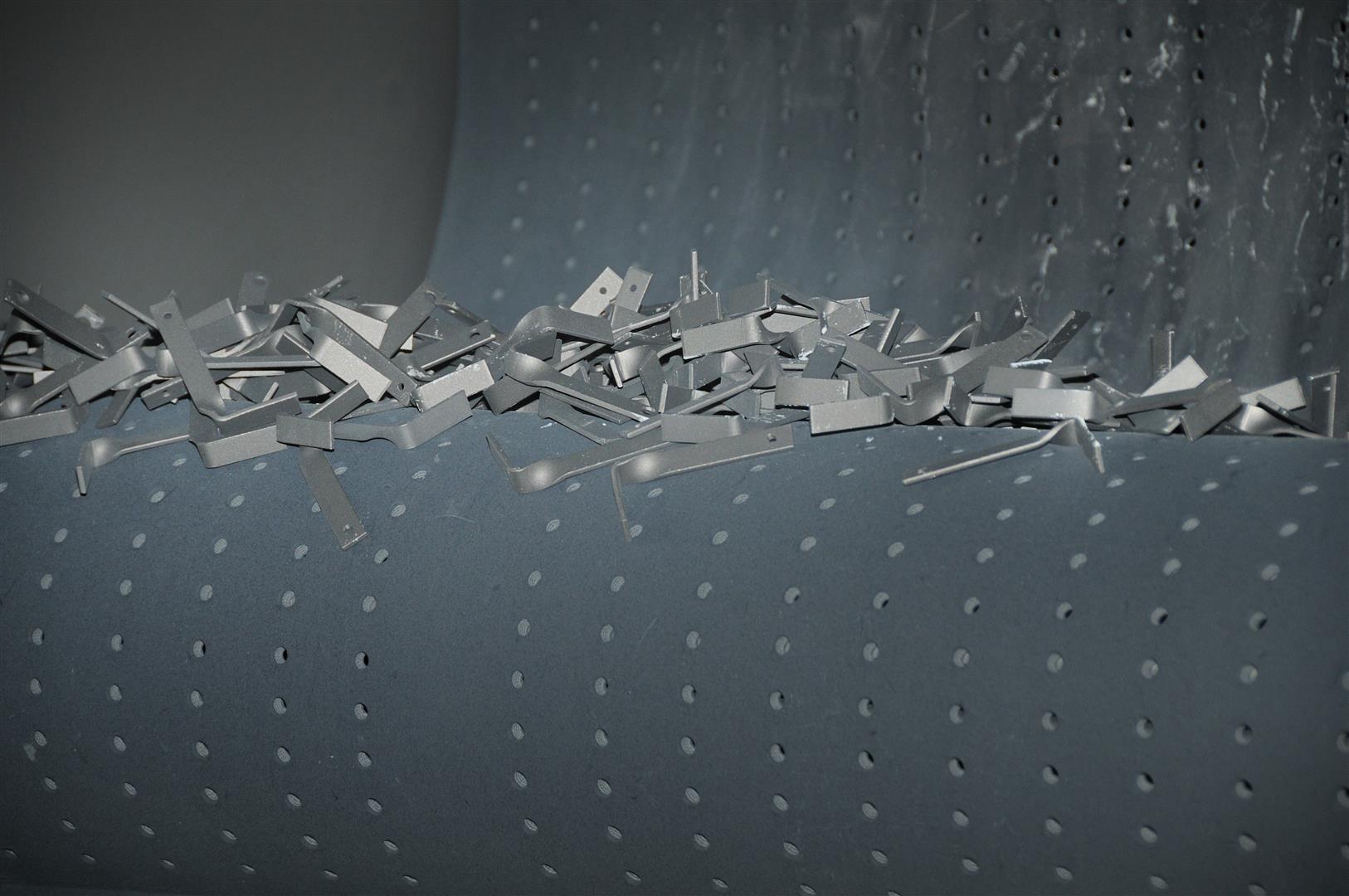

Tumble shotblasting plant

For the treatment of mass production small parts, A complete 360 ° treatment is enabled through ongoing rolling around of the parts in the blasting chamber.

Technical data:

Minimum unit size : 2,5 cm wide * 2,5 cm long* 2,5 cm high

Unit weight/max weight: 350 kg

STS Sundern

STS Sundern